Product Overview

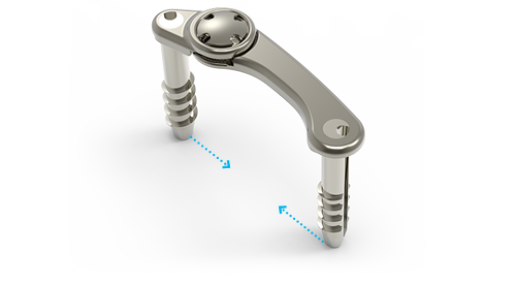

The Acumed Ratcheting Compression Plating System is designed to provide fixation for many fusions and osteotomies in the foot and utilizes a unique, built-in ratcheting hub that allows the surgeon to generate, incrementally increase, and retain mechanical compression. The Ratcheting Compression Plate integrates a plate span, cannulated and threaded legs, and a ratcheting hub into a stand-alone implant.

Related Documents

360° Rotation

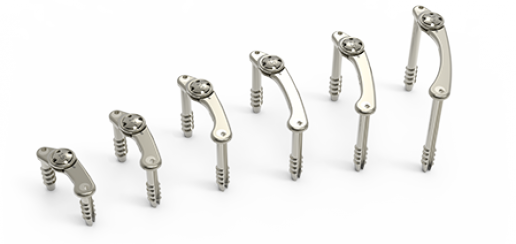

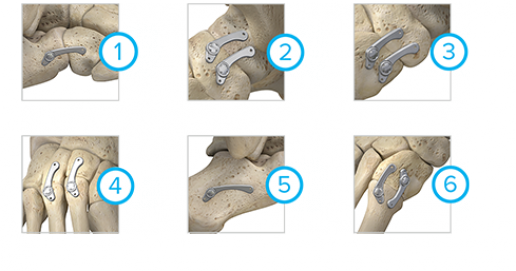

Shown: Ratcheting Compression plates on-bone

Plate Family

Ratcheting Compression Plates come in six sizes to fit the requirements of different indications. Plate bridge lengths range from 15 to 30 mm to accommodate a wide variety of foot and ankle indications. Leg lengths range from 11 to 25 mm.

Most Common Indications

The Ratcheting Compression Plating System is designed to address the following biomechanical challenges in surgeries of the foot: joint stabilization; initial and retained compression; cyclic loading; and ease of application.

The most common indications the system is intended for are:

- Calcaneo-cuboid fusions

- Talo-navicular fusions

- Navicular-cuneiform fusions

- Tarsal-metatarsal fusions

- Dwyer osteotomies

- Lapidus arthrodesis

Biomechanical Testing

During biomechanical testing, a competitive bone staple was used as a test control to evaluate the performance of the Ratcheting Compression Plate, including compression testing, four-point bending, cyclic loading, and pullout strength. See Technical Monograph for details.

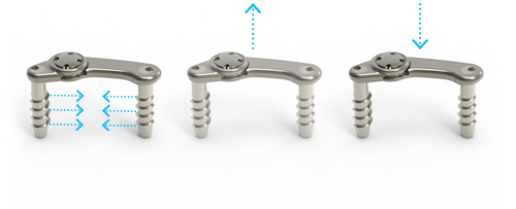

Linear Leg Travel

The primary function of the threads is to maximize the pullout resistance of the construct. As the ratcheting hub advances, the threading on the leg closest to the ratchet turns counterclockwise, engaging the bone. The threading on the leg furthest from the ratchet turns clockwise, engaging the bone. This engagement is responsible for the pullout resistance.

| Size | 15 mm | 17 mm | 20 mm | 25 mm | 30 mm |

| Total Travel | 3.4 mm | 3.6 mm | 3.7 mm | 3.9 mm | 4 mm |

| Per Click | 0.5 mm | 0.5 mm | 0.5 mm | 0.5 mm | 0.5 mm |

How Actuation Works

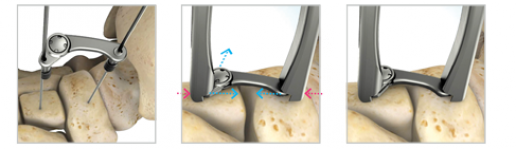

After each implant leg is inserted over the guide wire and seated on the surface of the bone, each end of the Compression Tool is threaded over the guide wire.

The ends of the tool are seated on either side of the plate span. The finger holes on the Compression Tool are then squeezed together. This action applies pressure (indicated in red) to the sides of the implant and activates the ratchet mechanism.

As the ratchet actuates, the ratchet hub rotates and makes an audible "click." Each click drives the component legs in line closer together (indicated in blue).

Image Gallery

no results for this query?

query = SELECT guid, post_title, p.post_status, post_excerpt, p.id FROM `wp_term_relationships` r left join wp_posts p on p.id = r.object_id left join wp_terms wpt on wpt.term_id = r.term_taxonomy_id where r.term_taxonomy_id = wpt.term_id and p.post_type = 'attachment' and (p.post_status = 'inherit' or p.post_status = 'publish') and (p.post_mime_type = 'image/jpg' or p.post_mime_type = 'image/png') and wpt.name = 'Ratcheting Compression Plating System'